Sewer Line Pipe Bursting

Trenchless Replacement of Sewer Line via Pipe Bursting

PUCC collaborated with industry professionals at the turn of the millennium to utilize trenchless technology via the pipe burst method as a possible solution for replacement of aging sewer and water utilities. Cities, municipalities and engineers in Tennessee and Virginia teamed with PUCC in the early 2000s to try the pipe burst method as an alternative to the traditional dig and replace method. Early on the sewer pipe burst pilot projects proved successful in solving I/I problems for many system owners including the City of Kingsport, Knoxville Utilities Board and South Boston, VA. Today with over two million linear foot installed, PUCC crews provide pipe bursting services that offer its customers the following benefits:

- It is trenchless. Disruption to city streets, lawns and businesses is minimal.

- It allows for the upsizing of existing lines

- The new pipe, typically HDPE pipe is strong, yet flexible, making ideal for tough situations.

- Pipe Bursting is economical compared to open trench methods in many instances.

Pipe Bursting Technical Information

Pipe Bursting Basics

![]()

The basic idea behind pipe bursting is simple. During the process a bursting tool is guided an existing fracturable pipe by a constant tension winch. The tool is often equipped with an expander that is larger than the existing or host pipe. As the tool travels through the host pipe its percussive action effectively breaks apart the pipe. The expander forces the fragments into the surrounding soil while the new pipe is pulled in simultaneously.

Advantages

Pipe bursting is an attractive replacement method for several reasons.

- First, it is trenchless. Disruption to city streets, lawns and business is minimal.

- Pipe bursting is the only trenchless method of rehabilatation or replacement that allows for the upsizing of existing lines.

- The new pipe, typically HDPE pipe is strong, yet flexible, making it ideal for tough installations.

- Pipe bursting is economical compared to open trench methods in many instances.

History

The pipe bursting method was derived from the concepts found in pneumatic piercing tools. These tools have been widely used since the 1960s. In 1981, Contractors DJ Ryan and Sons LTD along with British Gas (now Advantica Technologies) successfully ran a piercing tool through an existing cast iron gas line in England and pipe bursting was born.

At the time, there was a great deal of aging cast iron gas mains that needed to be replaced. Being able to replace those lines without open cutting narrow streets and sidewalks and possibly damaging historic locations was very appealing. In addition, both the gas and water markets in Europe were ripe for small diameter pipe bursting.

The basic idea behind pipe bursting is simple. During the process a bursting tool is guided an existing fracturable pipe by a constant tension winch. The tool is often equipped with an expander that is larger than the existing or host pipe. As the tool travels through the host pipe its percussive action effectively breaks apart the pipe. The expander forces the fragments into the surrounding soil while the new pipe is pulled in simultaneously. (See Animation)

Shortly thereafter the first attempts with piercing tools, manufacturers began producing tools specifically for pipe bursting.

North America

The big push for pipe bursting in the U.S. began in the late 1980s and early 1990s in the sewer market. Municipalities around the United States have been looking for ways to mitigate Inflow and Infiltration problems in their sanitary and storm sewer systems, in order to meet environmental standards and optimize treatment capacity levels.

Many improvement and advancements in pipe bursting equipment have taken place since its initial development. Pipe bursting equipment design specifically for lateral replacement is now available. In addition, powerful static bursting equipment has made bursting ductile iron and steel pipe possible. ![]()

The Development and Growth of Pipe Bursting

Narrow streets and historic locations typical in Europe prompted the development of pipe bursting.The pipe bursting method was derived from the concepts found in pneumatic piercing tools. These tools have been widely used since the 1960s. In 1981, Contractors DJ Ryan and Sons LTD along with British Gas (now Advantica Technologies) successfully ran a piercing tool through an existing cast iron gas line in England and pipe bursting was born.

At the time, there was a great deal of aging cast iron gas mains that needed to be replaced. Being able to replace those lines without open cutting narrow streets and sidewalks and possibly damaging historic locations was very appealing. In addition, both the gas and water markets in Europe were ripe for small diameter pipe bursting.

The basic idea behind pipe bursting is simple. During the process a bursting tool is guided an existing fracturable pipe by a constant tension winch. The tool is often equipped with an expander that is larger than the existing or host pipe. As the tool travels through the host pipe its percussive action effectively breaks apart the pipe. The expander forces the fragments into the surrounding soil while the new pipe is pulled in simultaneously. (See Animation)

Shortly thereafter the first attempts with piercing tools, manufacturers began producing tools specifically for pipe bursting.

North America

The big push for pipe bursting in the U.S. began in the late 1980s and early 1990s in the sewer market. Municipalities around the United States have been looking for ways to mitigate Inflow and Infiltration problems in their sanitary and storm sewer systems, in order to meet environmental standards and optimize treatment capacity levels.

Many improvement and advancements in pipe bursting equipment have taken place since its initial development. Pipe bursting equipment design specifically for lateral replacement is now available. In addition, powerful static bursting equipment has made bursting ductile iron and steel pipe possible.

Size Ranges

![]()

Tools are available for bursting, replacing and upsizing pipe from 4 to 54 inches in diameter. Size for size replacement through pipe bursting and even a one diameter size increase is very routine.

Upsizing

![]()

Upsizing the existing pipe by 25% is a rather common occurrence, although much depends on soil conditions. Challenging projects fall between a 25% and 50% increase of the host pipe diameter. While many of these projects have been successfully completed, each project must be evaluated on an individual basis. Increases of 50% to 125% are considered experimental. Again, many projects in this range have been completed, but there are many variables that need to be considered before attempting an upsize of this kind.

Materials to Burst

Cast Iron • Concrete • Asbestos Cement (ACP) • Reinforced Concrete Pipe (RCP) • PVC • Vitrified Clay Pipe (VCP) • Truss • Techite • Ductile Iron • Steel

Materials to Install

High Density Polyethylene (HDPE) • Ductile Iron • PVC • Steel

Equipment

The Development and Growth of Pipe Bursting

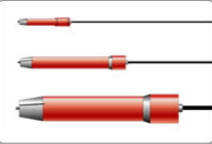

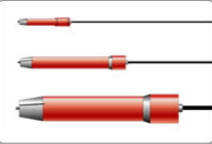

Pneumatic Tool - Pneumatic bursting relies on the percussive action of a pneumatically powered bursting tool. The pneumatic bursting tool is basically a piston within a casing. Compressed air propels the piston within the casing. The impact of the piston drives the tool.

Pneumatic Tool - Pneumatic bursting relies on the percussive action of a pneumatically powered bursting tool. The pneumatic bursting tool is basically a piston within a casing. Compressed air propels the piston within the casing. The impact of the piston drives the tool.

The tool is guided through the host pipe by a constant tension winch. The repeated impacts of the piston create the percussive action need to fragment the existing pipe. An expander attached to the tool forces the fragments of host pipe into the surrounding soil.

Static Tool - Static bursting utilizes a hydraulically powered bursting unit to pull a bursting head, expander and new pipe through the host pipe. Often specially designed bladed rollers are used for bursting/splitting difficult pipe like ductile iron and steel.

Static Tool - Static bursting utilizes a hydraulically powered bursting unit to pull a bursting head, expander and new pipe through the host pipe. Often specially designed bladed rollers are used for bursting/splitting difficult pipe like ductile iron and steel.

Lateral Tool - Several types of lateral bursting tools are used for replacing house to main connections. Because lateral lines run under driveways, sidewalks, trees and landscaped yards, trenchless pipe bursting is particularly effective in lateral replacement situations.

Lateral Tool - Several types of lateral bursting tools are used for replacing house to main connections. Because lateral lines run under driveways, sidewalks, trees and landscaped yards, trenchless pipe bursting is particularly effective in lateral replacement situations.

Small diameter pneumatic tools are often used for lateral replacement. The tools are fast and easy to handle and can replace a range of pipe sizes. Specially designed static bursting equipment is also common for lateral projects. The static equipment is compact, portable and powerful. It can also navigate turns and bends in the line up to 45 degrees.

Winch - The constant tension, dual motor, twin capstan, variable speed winch is used to guide a pneumatic bursting tool through the host pipe. The winch’s design allows it to make adjustments for conditions that affect line speed during operation providing constant and consistent pulling force.

Winch - The constant tension, dual motor, twin capstan, variable speed winch is used to guide a pneumatic bursting tool through the host pipe. The winch’s design allows it to make adjustments for conditions that affect line speed during operation providing constant and consistent pulling force.

Expander - Expanders come in various shapes and sizes depending on the specific bursting application. The expander forces the fragmented host pipe into the surrounding soil. In the case of an upsize of the original pipe, the expander also creates the annular space needed to accommodate the new pipe. As the name implies, rear expanders are either bolted or strapped on the rear of pneumatic bursting tools.

Expander - Expanders come in various shapes and sizes depending on the specific bursting application. The expander forces the fragmented host pipe into the surrounding soil. In the case of an upsize of the original pipe, the expander also creates the annular space needed to accommodate the new pipe. As the name implies, rear expanders are either bolted or strapped on the rear of pneumatic bursting tools.

Front expanders are placed in the front of pneumatic tools, typically reversible tools. Expanders for static bursting have the same function as expanders for pneumatic bursting. In static bursting the expander often follows a set of specially designed bladed rollers that score or split the pipe before the expander comes in contact with it.

Air Compressor - Sizing an air compressor for a bursting project depends on the size of the pneumatic bursting tool being used. The smallest bursting tools require less than 100 CFM to operate, while the largest bursting tools require over 1,700 CFM. Large bursting operations will sometimes require two compressors working in tandem. The length of the burst is also a consideration in choosing an air compressor because PSI will drop within the air hose over long distances.

Air Compressor - Sizing an air compressor for a bursting project depends on the size of the pneumatic bursting tool being used. The smallest bursting tools require less than 100 CFM to operate, while the largest bursting tools require over 1,700 CFM. Large bursting operations will sometimes require two compressors working in tandem. The length of the burst is also a consideration in choosing an air compressor because PSI will drop within the air hose over long distances.

Guide heads - Guide heads are used in rear expander pneumatic bursting situations. The guide head serves several purposes. First, it helps keep the bursting tool on track during operations. Second, it allows the tool to get into the pipe and break it from the inside, its weakest point. Often the guide head is equipped with cutting blades that help in bursting difficult pipe materials. The extra tool length the guide head adds helps protect the winch line from shards pipe as well.

Guide heads - Guide heads are used in rear expander pneumatic bursting situations. The guide head serves several purposes. First, it helps keep the bursting tool on track during operations. Second, it allows the tool to get into the pipe and break it from the inside, its weakest point. Often the guide head is equipped with cutting blades that help in bursting difficult pipe materials. The extra tool length the guide head adds helps protect the winch line from shards pipe as well.

Bentonite Pump - Bentonite mixing and delivery systems are commonly used in pipe bursting applications to reduce friction and provide lubrication in difficult soil conditions. Portable mixing and pumping units are used to mix and deliver the water and Bentonite mixture referred to commonly as mud. Rear expander pneumatic bursting tools can accommodate a bentonite manifold for delivery of bentonite during bursting operations.

Bentonite Pump - Bentonite mixing and delivery systems are commonly used in pipe bursting applications to reduce friction and provide lubrication in difficult soil conditions. Portable mixing and pumping units are used to mix and deliver the water and Bentonite mixture referred to commonly as mud. Rear expander pneumatic bursting tools can accommodate a bentonite manifold for delivery of bentonite during bursting operations.

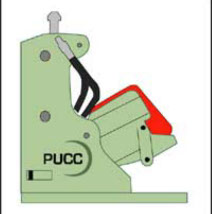

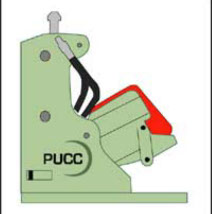

Pipe Fusion Machine - Pipe fusion is the method used to join sections of High Density Polyethylene pipe. A pipe fusion machine consists of several components. First, pipe clamps hold the two sections of HDPE that are going to be joined. Second a facer is used to create a smooth clean surface on each of the pipe ends for fusing. And third, a special heating element used to heat each end of pipe to the temperature needed for fusing. After each of the ends of pipe are faced and heated, they are pressed together to form the joint-free bond. In the case of small diameter pipe the fusing process can be accomplished, for the most part, manually. Larger diameter pipe requires larger automated fusing equipment.

Pipe Fusion Machine - Pipe fusion is the method used to join sections of High Density Polyethylene pipe. A pipe fusion machine consists of several components. First, pipe clamps hold the two sections of HDPE that are going to be joined. Second a facer is used to create a smooth clean surface on each of the pipe ends for fusing. And third, a special heating element used to heat each end of pipe to the temperature needed for fusing. After each of the ends of pipe are faced and heated, they are pressed together to form the joint-free bond. In the case of small diameter pipe the fusing process can be accomplished, for the most part, manually. Larger diameter pipe requires larger automated fusing equipment.

Pneumatic Tool - Pneumatic bursting relies on the percussive action of a pneumatically powered bursting tool. The pneumatic bursting tool is basically a piston within a casing. Compressed air propels the piston within the casing. The impact of the piston drives the tool.

Pneumatic Tool - Pneumatic bursting relies on the percussive action of a pneumatically powered bursting tool. The pneumatic bursting tool is basically a piston within a casing. Compressed air propels the piston within the casing. The impact of the piston drives the tool.The tool is guided through the host pipe by a constant tension winch. The repeated impacts of the piston create the percussive action need to fragment the existing pipe. An expander attached to the tool forces the fragments of host pipe into the surrounding soil.

Static Tool - Static bursting utilizes a hydraulically powered bursting unit to pull a bursting head, expander and new pipe through the host pipe. Often specially designed bladed rollers are used for bursting/splitting difficult pipe like ductile iron and steel.

Static Tool - Static bursting utilizes a hydraulically powered bursting unit to pull a bursting head, expander and new pipe through the host pipe. Often specially designed bladed rollers are used for bursting/splitting difficult pipe like ductile iron and steel. Lateral Tool - Several types of lateral bursting tools are used for replacing house to main connections. Because lateral lines run under driveways, sidewalks, trees and landscaped yards, trenchless pipe bursting is particularly effective in lateral replacement situations.

Lateral Tool - Several types of lateral bursting tools are used for replacing house to main connections. Because lateral lines run under driveways, sidewalks, trees and landscaped yards, trenchless pipe bursting is particularly effective in lateral replacement situations.Small diameter pneumatic tools are often used for lateral replacement. The tools are fast and easy to handle and can replace a range of pipe sizes. Specially designed static bursting equipment is also common for lateral projects. The static equipment is compact, portable and powerful. It can also navigate turns and bends in the line up to 45 degrees.

Winch - The constant tension, dual motor, twin capstan, variable speed winch is used to guide a pneumatic bursting tool through the host pipe. The winch’s design allows it to make adjustments for conditions that affect line speed during operation providing constant and consistent pulling force.

Winch - The constant tension, dual motor, twin capstan, variable speed winch is used to guide a pneumatic bursting tool through the host pipe. The winch’s design allows it to make adjustments for conditions that affect line speed during operation providing constant and consistent pulling force.

Expander - Expanders come in various shapes and sizes depending on the specific bursting application. The expander forces the fragmented host pipe into the surrounding soil. In the case of an upsize of the original pipe, the expander also creates the annular space needed to accommodate the new pipe. As the name implies, rear expanders are either bolted or strapped on the rear of pneumatic bursting tools.

Expander - Expanders come in various shapes and sizes depending on the specific bursting application. The expander forces the fragmented host pipe into the surrounding soil. In the case of an upsize of the original pipe, the expander also creates the annular space needed to accommodate the new pipe. As the name implies, rear expanders are either bolted or strapped on the rear of pneumatic bursting tools.Front expanders are placed in the front of pneumatic tools, typically reversible tools. Expanders for static bursting have the same function as expanders for pneumatic bursting. In static bursting the expander often follows a set of specially designed bladed rollers that score or split the pipe before the expander comes in contact with it.

Air Compressor - Sizing an air compressor for a bursting project depends on the size of the pneumatic bursting tool being used. The smallest bursting tools require less than 100 CFM to operate, while the largest bursting tools require over 1,700 CFM. Large bursting operations will sometimes require two compressors working in tandem. The length of the burst is also a consideration in choosing an air compressor because PSI will drop within the air hose over long distances.

Air Compressor - Sizing an air compressor for a bursting project depends on the size of the pneumatic bursting tool being used. The smallest bursting tools require less than 100 CFM to operate, while the largest bursting tools require over 1,700 CFM. Large bursting operations will sometimes require two compressors working in tandem. The length of the burst is also a consideration in choosing an air compressor because PSI will drop within the air hose over long distances. Guide heads - Guide heads are used in rear expander pneumatic bursting situations. The guide head serves several purposes. First, it helps keep the bursting tool on track during operations. Second, it allows the tool to get into the pipe and break it from the inside, its weakest point. Often the guide head is equipped with cutting blades that help in bursting difficult pipe materials. The extra tool length the guide head adds helps protect the winch line from shards pipe as well.

Guide heads - Guide heads are used in rear expander pneumatic bursting situations. The guide head serves several purposes. First, it helps keep the bursting tool on track during operations. Second, it allows the tool to get into the pipe and break it from the inside, its weakest point. Often the guide head is equipped with cutting blades that help in bursting difficult pipe materials. The extra tool length the guide head adds helps protect the winch line from shards pipe as well. Bentonite Pump - Bentonite mixing and delivery systems are commonly used in pipe bursting applications to reduce friction and provide lubrication in difficult soil conditions. Portable mixing and pumping units are used to mix and deliver the water and Bentonite mixture referred to commonly as mud. Rear expander pneumatic bursting tools can accommodate a bentonite manifold for delivery of bentonite during bursting operations.

Bentonite Pump - Bentonite mixing and delivery systems are commonly used in pipe bursting applications to reduce friction and provide lubrication in difficult soil conditions. Portable mixing and pumping units are used to mix and deliver the water and Bentonite mixture referred to commonly as mud. Rear expander pneumatic bursting tools can accommodate a bentonite manifold for delivery of bentonite during bursting operations. Pipe Fusion Machine - Pipe fusion is the method used to join sections of High Density Polyethylene pipe. A pipe fusion machine consists of several components. First, pipe clamps hold the two sections of HDPE that are going to be joined. Second a facer is used to create a smooth clean surface on each of the pipe ends for fusing. And third, a special heating element used to heat each end of pipe to the temperature needed for fusing. After each of the ends of pipe are faced and heated, they are pressed together to form the joint-free bond. In the case of small diameter pipe the fusing process can be accomplished, for the most part, manually. Larger diameter pipe requires larger automated fusing equipment.

Pipe Fusion Machine - Pipe fusion is the method used to join sections of High Density Polyethylene pipe. A pipe fusion machine consists of several components. First, pipe clamps hold the two sections of HDPE that are going to be joined. Second a facer is used to create a smooth clean surface on each of the pipe ends for fusing. And third, a special heating element used to heat each end of pipe to the temperature needed for fusing. After each of the ends of pipe are faced and heated, they are pressed together to form the joint-free bond. In the case of small diameter pipe the fusing process can be accomplished, for the most part, manually. Larger diameter pipe requires larger automated fusing equipment.

Application

Sanitary Sewer - Sanitary sewer mains and laterals that are failing or undersized eventually need to be replaced. Over the last decade, the driving force in sanitary sewer replacement has been the mitigation of Inflow and Infiltration. Leaky sanitary sewer mains and laterals fill with rain water, water that should be flowing through storm sewers. Ultimately municipalities spend millions of dollars a year treating water that doesn't need to be treated at waste water treatment facilities. Replacing leaky mains and laterals helps solve the problem. Capacity is also an issue.

Sanitary Sewer - Sanitary sewer mains and laterals that are failing or undersized eventually need to be replaced. Over the last decade, the driving force in sanitary sewer replacement has been the mitigation of Inflow and Infiltration. Leaky sanitary sewer mains and laterals fill with rain water, water that should be flowing through storm sewers. Ultimately municipalities spend millions of dollars a year treating water that doesn't need to be treated at waste water treatment facilities. Replacing leaky mains and laterals helps solve the problem. Capacity is also an issue.

Typical sanitary sewer pipes: VCP, Cast Iron, RCP and ACP

Typical sizes: Laterals 4 to 6 inches, Mains 8 to 36 inches and larger

Storm Sewer - Storm sewers like any other underground utility are subject to deterioration. As infrastructure ages, it will eventually need to be replaced. This is the case with storm sewer systems. With urban development often redirecting natural storm water flows, storm sewer capacity can also be an issue .

Storm Sewer - Storm sewers like any other underground utility are subject to deterioration. As infrastructure ages, it will eventually need to be replaced. This is the case with storm sewer systems. With urban development often redirecting natural storm water flows, storm sewer capacity can also be an issue .

Typical Storm sewer: Concrete, RCP and ACP

Typical sizes: 8 to 18 inches and larger

Water - Water mains and services are being replaced around the United States for a similar reason as sanitary systems. But instead of letting water in, failing water systems are letting potable water out, a problem known as ex-filtration. Water is a valuable resource and it is estimated that as much as 40% of the potable water pumped worldwide is unaccounted for, meaning it leaked out of the system before reaching its destination. The need to replace water systems is growing quickly.

Water - Water mains and services are being replaced around the United States for a similar reason as sanitary systems. But instead of letting water in, failing water systems are letting potable water out, a problem known as ex-filtration. Water is a valuable resource and it is estimated that as much as 40% of the potable water pumped worldwide is unaccounted for, meaning it leaked out of the system before reaching its destination. The need to replace water systems is growing quickly.

Typical water pipes: Cast Iron, Ductile Iron, Galvanized steel

Typical sizes: Services 1/2 to 2 inches, Mains 6 to 12 inches and larger

Gas - For the gas industry capacity is a large motivator for the replacement of the gas mains and services. With the highly competitive nature of the gas industry, meeting demand and doing it efficiently is always a top priority. Increasing capacity through trenchless pipe bursting is one way to meet the goal. As any other utility, the gas industry is also faced with and aging infrastructure.

Gas - For the gas industry capacity is a large motivator for the replacement of the gas mains and services. With the highly competitive nature of the gas industry, meeting demand and doing it efficiently is always a top priority. Increasing capacity through trenchless pipe bursting is one way to meet the goal. As any other utility, the gas industry is also faced with and aging infrastructure.

Typical gas pipes: Cast Iron, Ductile Iron, Galvanized steel, PVC

Typical sizes: Services 1/2 to 2 inches, Mains 6 to 10 inches

Sanitary Sewer - Sanitary sewer mains and laterals that are failing or undersized eventually need to be replaced. Over the last decade, the driving force in sanitary sewer replacement has been the mitigation of Inflow and Infiltration. Leaky sanitary sewer mains and laterals fill with rain water, water that should be flowing through storm sewers. Ultimately municipalities spend millions of dollars a year treating water that doesn't need to be treated at waste water treatment facilities. Replacing leaky mains and laterals helps solve the problem. Capacity is also an issue.

Sanitary Sewer - Sanitary sewer mains and laterals that are failing or undersized eventually need to be replaced. Over the last decade, the driving force in sanitary sewer replacement has been the mitigation of Inflow and Infiltration. Leaky sanitary sewer mains and laterals fill with rain water, water that should be flowing through storm sewers. Ultimately municipalities spend millions of dollars a year treating water that doesn't need to be treated at waste water treatment facilities. Replacing leaky mains and laterals helps solve the problem. Capacity is also an issue.Typical sanitary sewer pipes: VCP, Cast Iron, RCP and ACP

Typical sizes: Laterals 4 to 6 inches, Mains 8 to 36 inches and larger

Storm Sewer - Storm sewers like any other underground utility are subject to deterioration. As infrastructure ages, it will eventually need to be replaced. This is the case with storm sewer systems. With urban development often redirecting natural storm water flows, storm sewer capacity can also be an issue .

Storm Sewer - Storm sewers like any other underground utility are subject to deterioration. As infrastructure ages, it will eventually need to be replaced. This is the case with storm sewer systems. With urban development often redirecting natural storm water flows, storm sewer capacity can also be an issue .Typical Storm sewer: Concrete, RCP and ACP

Typical sizes: 8 to 18 inches and larger

Water - Water mains and services are being replaced around the United States for a similar reason as sanitary systems. But instead of letting water in, failing water systems are letting potable water out, a problem known as ex-filtration. Water is a valuable resource and it is estimated that as much as 40% of the potable water pumped worldwide is unaccounted for, meaning it leaked out of the system before reaching its destination. The need to replace water systems is growing quickly.

Water - Water mains and services are being replaced around the United States for a similar reason as sanitary systems. But instead of letting water in, failing water systems are letting potable water out, a problem known as ex-filtration. Water is a valuable resource and it is estimated that as much as 40% of the potable water pumped worldwide is unaccounted for, meaning it leaked out of the system before reaching its destination. The need to replace water systems is growing quickly.Typical water pipes: Cast Iron, Ductile Iron, Galvanized steel

Typical sizes: Services 1/2 to 2 inches, Mains 6 to 12 inches and larger

Gas - For the gas industry capacity is a large motivator for the replacement of the gas mains and services. With the highly competitive nature of the gas industry, meeting demand and doing it efficiently is always a top priority. Increasing capacity through trenchless pipe bursting is one way to meet the goal. As any other utility, the gas industry is also faced with and aging infrastructure.

Gas - For the gas industry capacity is a large motivator for the replacement of the gas mains and services. With the highly competitive nature of the gas industry, meeting demand and doing it efficiently is always a top priority. Increasing capacity through trenchless pipe bursting is one way to meet the goal. As any other utility, the gas industry is also faced with and aging infrastructure.Typical gas pipes: Cast Iron, Ductile Iron, Galvanized steel, PVC

Typical sizes: Services 1/2 to 2 inches, Mains 6 to 10 inches

Launch and Exit Pits

Launch and exit pits vary from project to project. Pits need to be long enough and wide enough to accomodate the bursting equipment. The depth of the pits will vary by the depth of the host pipe. While HDPE is relatively flexible, special attention must be paid to the angle at which the pipe enters the launch pit and ultimately the host pipe. So, the depth of the host pipe not only effects the depth of the pit, it effects the length of the pit as well. Launch pits that exceed a specific depth must be properly shored to ensure safety.

Typical launch pits are large enough to accomodate bursting tool and gentle bend radius on HDPE.

Exit pit is just large enough for bursting tool removal.

Typical launch pits are large enough to accomodate bursting tool and gentle bend radius on HDPE.

Exit pit is just large enough for bursting tool removal.

Connections

SEWER SERVICE CONNECTIONS WHEN PIPE BURSTING SEWER LINES

Studies have shown that services account for roughly half of Inflow/Infiltration problems.

Water tables in trenches are raised when problems associated with the main are corrected. If the service reconnects are not watertight, return on investment spent on correcting the main is diminished.

Therefore, whenever possible hard reconnections at services are advisable when addressing Inflow/Infiltration problems.

Most agree that a hard reconnect is the most cost effective method to solve Inflow/Infiltration problems.

Because service connections are fragmented along with the main during the pipe burst process, services associated with pipe bursting must be reconnected with a hard reconnect at the main.

The types of sewer connections to a sewer main are:

Studies have shown that services account for roughly half of Inflow/Infiltration problems.

Water tables in trenches are raised when problems associated with the main are corrected. If the service reconnects are not watertight, return on investment spent on correcting the main is diminished.

Therefore, whenever possible hard reconnections at services are advisable when addressing Inflow/Infiltration problems.

Most agree that a hard reconnect is the most cost effective method to solve Inflow/Infiltration problems.

Because service connections are fragmented along with the main during the pipe burst process, services associated with pipe bursting must be reconnected with a hard reconnect at the main.

The types of sewer connections to a sewer main are:

- Electrofuse Saddle

- Rubber Saddle

- PVC Saddle

- Inserta Tee (Registered Patent)